Why trust Extraction Solutions to design your new system?

As a family run business you can enjoy piece of mind that your extraction is in good hands. ESL have close relationships with many customers going back over a decade

Reduce your energy bills with a smart ‘on demand’ extraction system

A small reduction in extraction volume can result in a large reduction in fan power and your energy bills. You can see for yourself using this handy energy saving calculator, contact one of our engineers to find out how you can make savings and reduce your carbon footprint.

See how much you could save with this simple calculator

Reduce your energy bills with a smart ‘on demand’ extraction system

A small reduction in extraction volume can result in a large reduction in fan power and your energy bills. You can see for yourself using this handy energy saving calculator, contact one of our engineers to find out how you can make savings and reduce your carbon footprint.

See how much you could save with this simple calculator

Understanding your process to deliver the right strategy

Our design procedure involves looking into your manufacturing processes, products, and materials. Anything and everything that could effect the smooth running of your system, not just simply the extraction connections.

Usually seen as a necessary evil, a great extraction system can be the backbone of your business keeping production machinery clean, improving product quality and most importantly ensuring clean air in workplace.

Understanding your process to deliver the right strategy

Our design procedure involves looking into your manufacturing processes, products, and materials. Anything and everything that could effect the smooth running of your system, not just simply the extraction connections.

Usually seen as a necessary evil, a great extraction system can be the backbone of your business keeping production machinery clean, improving product quality and most importantly ensuring clean air in workplace.

Understanding your process to deliver the right strategy

Our design procedure involves looking into your manufacturing processes, products, and materials. Anything and everything that could effect the smooth running of your system, not just simply the extraction connections.

Usually seen as a necessary evil, a great extraction system can be the backbone of your business keeping production machinery clean, improving product quality and most importantly ensuring clean air in workplace.

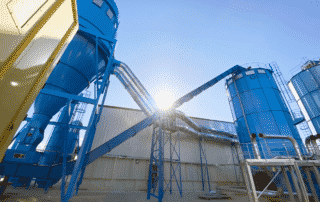

Case study projects